Designed to be adaptable

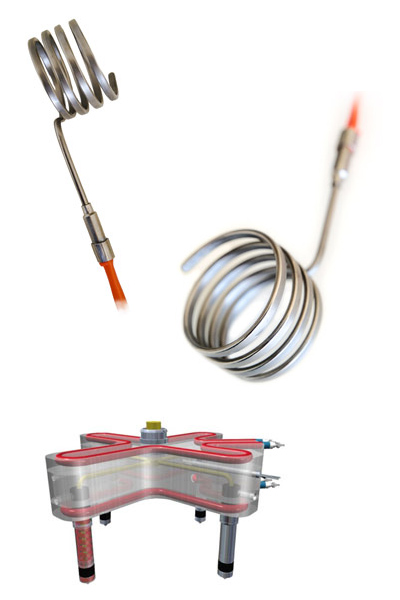

Coil Heater cartridges are especially recommended for the heating of cylinders and joints. These cartridges, despite their small diameter, have high heating power, distributing uniform heat up to 360C.

The heater wire is of the highest quality surrounded by a layer of magnesium oxide and enclosed in a stainless steel cover. Everything goes through a process of compression; giving it a longer life, as well as ensuring its reaching the required temperature.

As an option the cartridge heater can be hermetically sealed to prevent the entry of extraneous materials, moisture, fluids, etc.

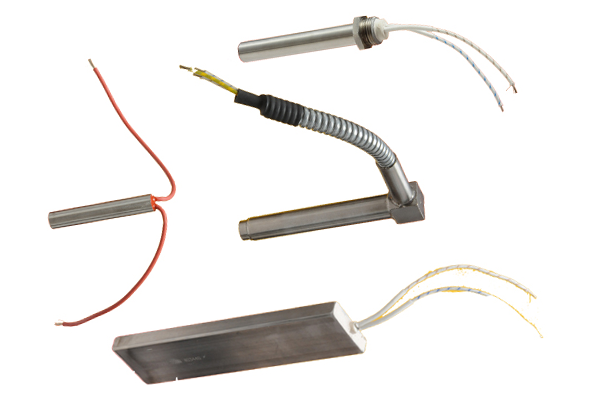

Variety of Endings & Terminations

As standard, the heaters are sold straight, but can be coiled to your specification.

| length | heated length | power | W/cm2 | 2.2 x 4.2 |

| 200 mm | 135 mm | 180 W | 5.40 | 200CH2242 |

| 265 mm | 200 mm | 200 W | 5.40 | 265CH2242 |

| 315 mm | 250 mm | 225 W | 5.40 | 315CH2242 |

| 345 mm | 280 mm | 250 W | 5.40 | 345CH2242 |

| 400 mm | 335 mm | 275 W | 5.40 | 400CH2242 |

| 450 mm | 385 mm | 300 W | 5.40 | 450CH2242 |

| 525 mm | 460 mm | 350 W | 5.40 | 525CH2242 |

| 600 mm | 535 mm | 400 W | 5.40 | 600CH2242 |

| 700 mm | 635 mm | 450 W | 5.40 | 700CH2242 |

| 750 mm | 685 mm | 550 W | 5.40 | 750CH2242 |

| 800 mm | 735 mm | 625 W | 5.40 | 800CH2242 |

| 950 mm | 885 mm | 700 W | 5.40 | 950CH2242 |

| 1000 mm | 935 mm | 750 W | 5.40 | 1000CH2242 |

| 1175 mm | 1110 mm | 850 W | 5.40 | 1175CH2242 |

| 1400 mm | 1335 mm | 1000 W | 5.40 | 1400CH2242 |

| 1600 mm | 1535 mm | 1150 W | 5.40 | 1600CH2242 |

| 1800 mm | 1735 mm | 1200 W | 5.40 | 1800CH2242 |

| 2000 mm | 1935 mm | 1250 W | 5.40 | 2000CH2242 |

(*) Include Thermocouple type "J", Teflon or Fluoropolymer-Nickel-plated copper leads, and fibreglass protection sleeve of 1000mm length.

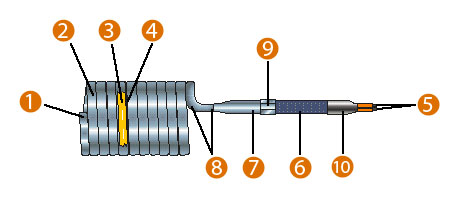

- Welded watertight base tig, resists pressure up to 60kg/cm2.

- Stainless steel 304.

- Checked pure granulometric magnesium oxide.

- Nickel-chromium heater wire. Melting point 1400ºC.

- Conductor lead.

- Metal braided protection.

- Metal base adapter 25mm.

- Inactive area 65mm.

- Pressed tube for fastening.

- Refractive sheath.

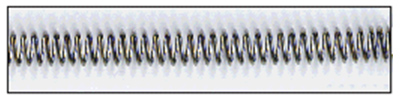

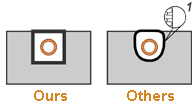

Our manufacturing system, together with its CAM system, makes it possible to evenly separate the spirals, thereby guaranteeing the same temperature around the whole perimeter and length of the cartridge. Obtaining a uniform and lasting temperature output.

Endings & Exits: positioning of the connections

Axial Output Ref. "Coil A"

Tangential Output Ref. "Coil B"

Lateral Output Ref. "Coil C"

Radial Output Ref. "Coil D"

Maluable Resistences 6 x 6mm2 - cross sectional area

For heating of molds

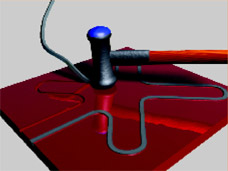

Our square-sectioned resistances are specially designed to be mouldeable to the required shape at room temperature. These heaters have been designed for heating all types of molds, particularly hot running systems.

These resistances have been developed and constructed with the highest quality of materials, which guarantees their reliability and long life. Their three-dimensional flexiblility allows the client to mold the resistance to any shape, including very tight angles and turns, by only applying a slight pressure. Being able to mold the resistance at room temperature allows fast and easy setup at the client's facility. The resistance's square shape simplifies the design of molds, and allows exact adjustment to the mold's cavity, thus enabling a thermal transmission that is superior to other products on the market.

Technical Data

| Heat intensity | Not exceeding 10wcm2 (recommended) |

| Power | Depends on the dimension |

| Current leakage (when cold) | <=0.1mA to 242 v. |

| Insulation (When cold) | <=5mA. to 500v. |

| Dielectric strength | 1500v. 1/second |

| Working temperature | 7 50ºG max. |

| Length tolerances | +/-2.5% |

| Section tolerances | +/- 0.1 |

| Cable length tolerances | +/-15 mm |

| Power tolerance (w) | +/- 10 % |

| Cold areas | Depends on length and diameter 5 - 15mm |

Enquiry Form

Complete our enquiry form or alternatively email us direct as sales@lojerproducts.co.uk or call 01635 865882