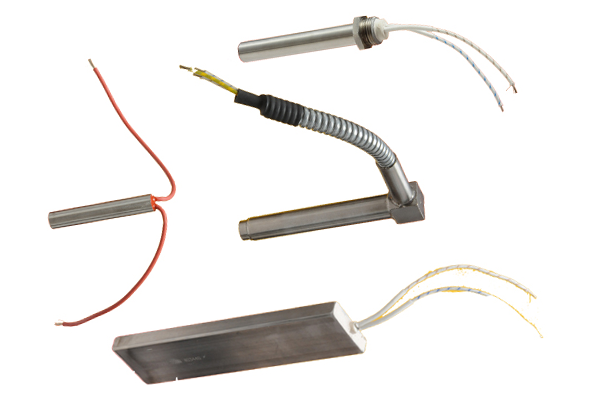

Temperature Sensors for Industry - LJRTOPE-361, 362, LJRTTJE-361, 363, LJRTKE-361, 362

Applicable for temperature measurement of liquid and gaseous media in high pressure conditions. This Sensor consists of sensing element placed in the thin-walled acid-resistant sheath with connector and flexible lead wire.

Specification

Temperature range / sensing element

-50÷400ºC Pt100 class B

-40÷400ºC K, J class 2

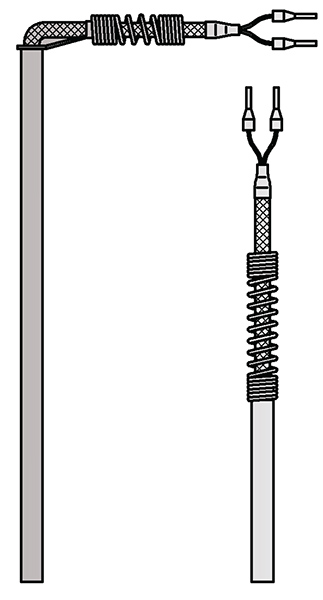

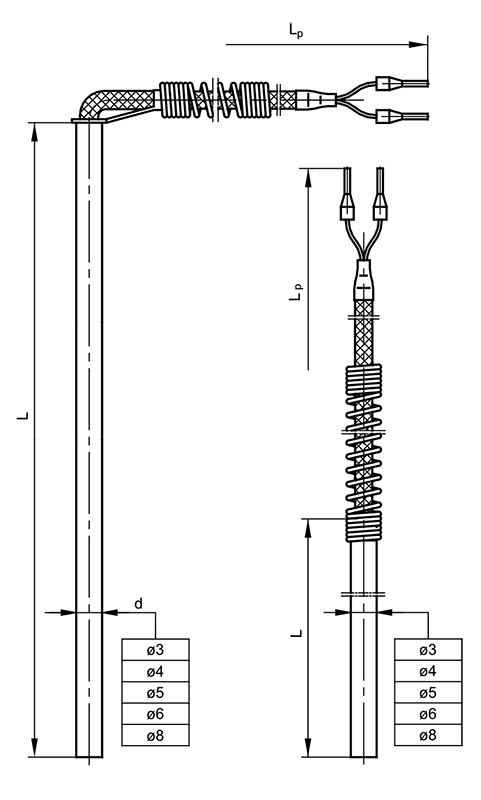

Thermowell

– material: steel 1.4541

– diameter d [mm]: 3, 4, 5, 6, 8

– length L[mm]: 30÷1000

Lead wire

– stranded Cu wire or stranded thermocouple wire: 0,22mm2

– fiberglass insulation, metal overbraid

– length Lp[m]: 1,5 (standard)

– Cu wire resistance~0,14 O/m = ~0,36ºC

Other parameters according to requirements

Options

Temperature transmitter application

Temperature transmitter with standard 4÷20mA, 0÷10V output signals and with the HART or PROFIBUS communication protocols can be installed in the control cabinet.

Non-standard design

Immersion length, shape and material of the sheath and other parameters can be customized per client request.

Compensation / Thermocouple wire insulations

| Insulation Material | Operating temperature range [°C] | Properties |

| PCW (PCV) | -10÷105 | Applied in mild environmental conditions. Waterproof and flexible. |

| Yc- polyvinylchloride | -10÷105 | Applied in mild environmental conditions. Waterproof and flexible. |

| FEP-teflon | -50÷200 | Resistant to oils, acids and other aggressive liquids. Good flexibility. |

| Si-silicone | -50÷180 | Waterproof, flexible. Applied in high humidity conditions. |

| Ws-fiberglass | -60÷400 | Good resistance to high temperature Low resistance to liquid penetration. |

| Notes: Additionally, copper or steel braids/shields are used on wires to prevent electrical noises, Increasing, at the same time, wire insulation resistance to mechanical damages. In case of longer wire lengths grounding may be needed to minimize the noise in measurement circuit | ||

Response time to temperature change dla Pt

| Thermowell diameter [mm] | Response time [s] |

| Ø6 | t 0,5= 12 |

| t 0,9= 55 | |

| Ø8 | t 0,5= 20 |

| t 0,9= 85 |

Tolerance for classes of sensors with resistors Pt acc. to PN-EN 60751

| Sensor classes | Range of application [°C] | Formula for calculating acceptable deviations [°C] |

| AA | 0÷150 | T = ±(0,10 + 0,0017 |t|) |

| A | -30÷300 | T = ±(0,15 + 0,002 |t|) |

| B | -50÷500 | T = ±(0,3 + 0,005 |t|) |

|t|- absolute value of temperature

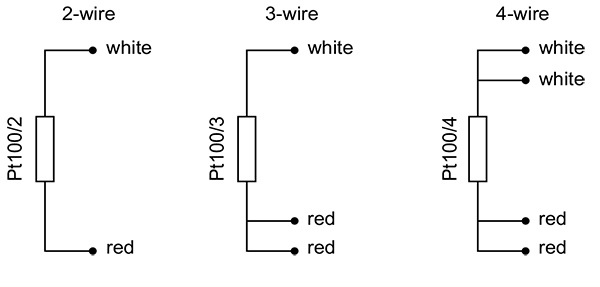

Measurement circuit

| 1 x Pt100 | 2 x Pt100 | 1 x TC | 2 x TC | ||||

| 2-wire | 3-wire | 4-wire | 2-wire | 3-wire | 4-wire | 2-wire | 3-wire |

| ✔ | ✔ | ✔ | X | X | X | ✔ | X |

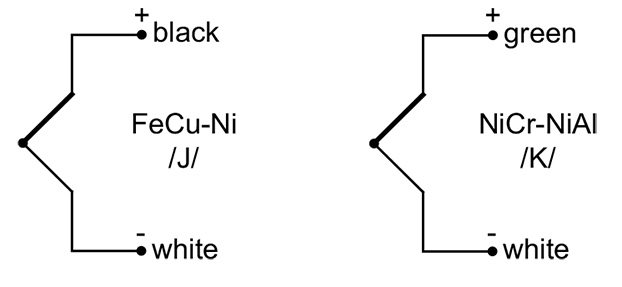

Tolerance for thermocouple classes acc. to PN-EN 60584

| Thermocouple type | Class 1 | Class 2 | ||

| Range of application [°C] | Tolerance [°C] | Range of application [°C] | Tolerance [°C] | |

| J Fe-CuNi |

from -40 to +375 from +375 to +750 |

±1,5 ±0,004 |t| |

from -40 to +333 from +333 to +750 |

±2,5 ±0,0075 |t| |

| K NiCr-NiAl |

from -40 to +375 from +375 to +1000 |

±1,5 ±0,004 |t| |

from -40 to +333 from +333 to +1200 |

±2,5 ±0,0075 |t| |

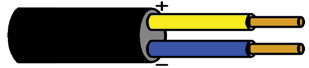

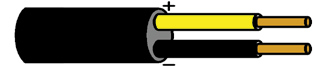

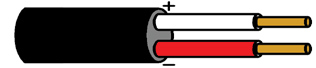

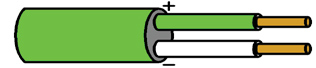

Connection schemes

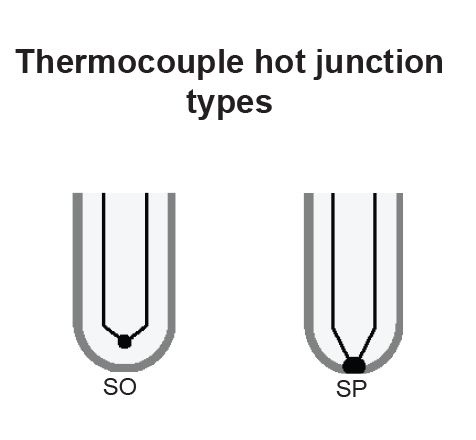

Pt100 (thermometric resistor)

TC (thermocouple)

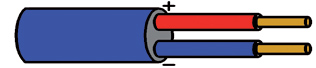

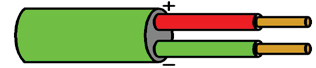

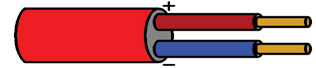

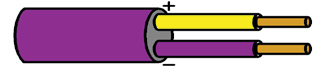

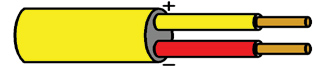

Cable types and colours acc. to the norm

EU

Thermocouple

J type

D

GB

F

USA

Thermocouple

K type

Enquiry Form

Complete our enquiry form or alternatively email us direct as sales@lojerproducts.co.uk or call 01635 865882